Users’ demand for reliable energy storage is constantly rising. As a professional lead acid battery factory, Mk Energy has also provided solutions to this series of challenges. Below we will tell you how a lead-acid battery factory implemented innovative solutions to overcome energy storage obstacles.

Technological Advances in Lead Acid Battery Factory Design

In the face of changes in the market environment, we have added advanced robotic systems and automated machinery to our production lines to make our lead acid battery factories more modern and computerized. This simplifies the manufacturing process and reduces manual work. Significantly improve the production speed and battery delivery time. We have incorporated energy-saving machinery into our lead-acid battery plant designs to improve energy efficiency, implemented intelligent grid systems, and integrated renewable energy sources. Enable a more sustainable and environmentally friendly manufacturing process. Implementation of lean manufacturing principles in lead-acid battery factory design is also becoming common throughout the energy storage market.

Electrolyte technology innovation in lead acid battery factory

We have upgraded our electrolyte technology to enable our lead acid battery factories to produce more competitive lead-acid batteries. Electrolyte additives are carefully formulated to enhance the electrolyte’s conductivity, stability, and performance. They help improve charge acceptance, reduce sulfation, and increase cycle life, addressing traditional limitations associated with lead-acid batteries. Low- and maintenance-free lead-acid batteries are enabled by innovations in gel and absorbed glass mat (AGM) electrolyte technology. These designs minimize the risk of acid leakage and allow for greater flexibility in battery placement. Improvements in valve-regulated lead-acid (VRLA) battery design have improved safety and expanded application range, with electrolyte retention technology that prevents electrolytes from flowing freely, making it spill-proof and suitable for use in various orientations.

Charging technology in lead-acid battery factory

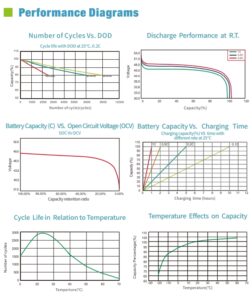

Regarding charging technology, we have developed intelligent charging algorithms that optimize charging curves based on the specific characteristics of lead-acid batteries, considering factors such as temperature, state of charge, and battery life. Intelligent charging ensures the battery receives the right amount of charge at the correct voltage and current levels, preventing overcharging and reducing the risk of sulfation. We also introduce multi-stage charging, which involves different charging stages. There are mainly bulk charging, absorption, floating, and sometimes equalization phases. Each stage has a specific purpose, such as quickly replenishing large amounts of charge, maintaining a float charge to sustain the battery, and equalizing the cell voltage to prevent stratification. This multi-stage charging technology improves the overall health and performance of lead-acid batteries.

Grid integrated solutions

Innovative grid technologies have been added to our lead acid battery factories to obtain more efficient energy storage. These technologies enable two-way communication between the lead-acid batteries and the power grid, enabling real-time monitoring, control and coordination. Smart grids enhance lead-acid battery response, aiding in load balancing, reducing stress on the grid during peak demand, and supporting more efficient use of energy. Microgrids also provide a degree of energy independence, allowing factories to optimize energy use, enhance resilience during grid outages, and potentially feed excess power back to the grid.

Sustainable practices in operations

Sustainable management involves the responsible management of raw materials, implementing strategies to minimize resource consumption, and utilizing recycled lead and plastic wherever possible. We have invested in energy-saving equipment, adopted advanced production technology, and implemented energy management systems to optimize energy consumption. Harnessing renewable energy sources, such as solar or wind power, further reduces the environmental footprint of these manufacturing facilities.

Grow in competition

Our lead-acid battery factory is providing more current energy storage solutions through battery technology advancements and sustainable development practices. By staying at the forefront of innovation, we can address current challenges and shape the future of energy storage solutions.