This article mainly introduces the side bulging problems and solutions after the square lithium battery is enlarged, and the problems and solutions for poor heat dissipation.

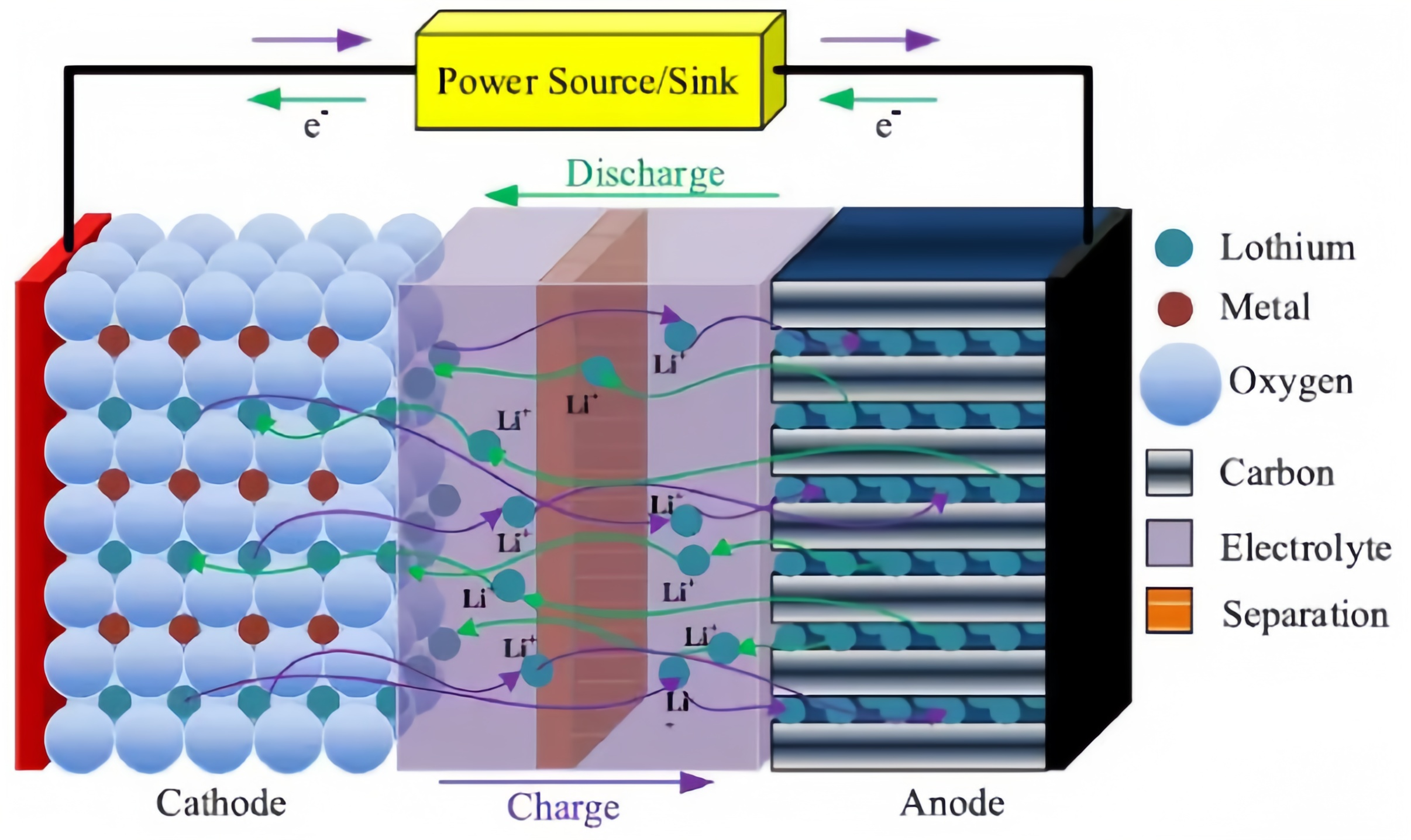

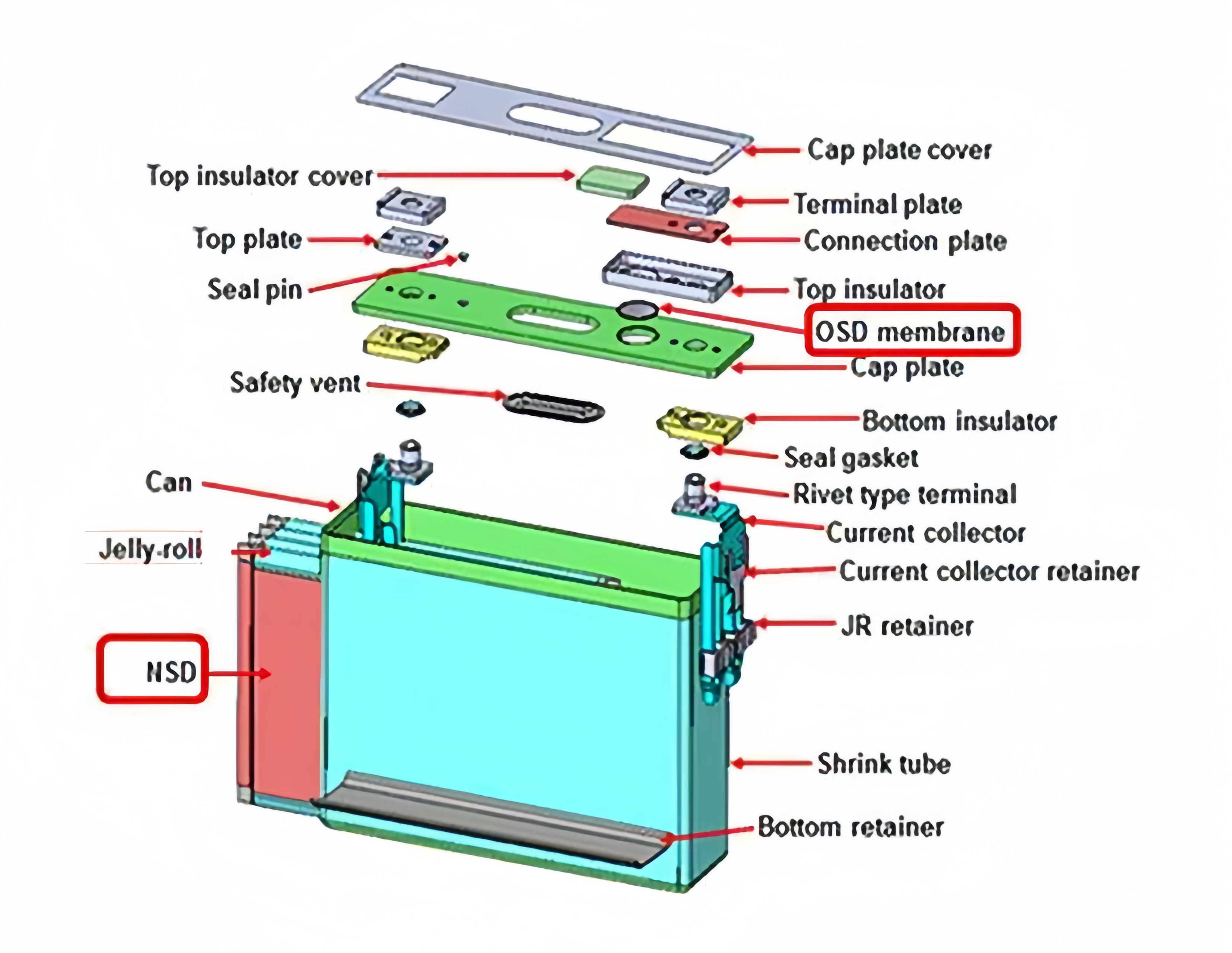

The main components of a typical square lithium battery include: top cover, case, positive plate, negative plate, separator, laminated or rolled sheets, insulation parts, safety components, etc. Among them, the two in the red circle are safety structures, NSD acupuncture safety device; OSD overcharge protection device. The shell is generally a steel shell or an aluminum shell. With the market’s pursuit of energy density and the advancement of production technology, aluminum shells have gradually become mainstream.

Side bulging problem

During the charging and discharging process of lithium-ion batteries, there is a certain pressure inside the battery (empirical data is 0.3~0.6 MPa). Under the same pressure, the larger the force-bearing area, the more serious the deformation of the battery shell wall.

Important reasons for battery expansion: gas is generated during the formation of SEI, and the air pressure in the battery increases. Due to the poor pressure resistance of the square battery planar structure, the shell deforms; the lattice parameters of the electrode material change during charging, causing The electrode expands, and the electrode expansion force acts on the casing, causing the battery casing to deform. During high-temperature storage, a small amount of electrolyte decomposes and the gas pressure increases due to temperature effects, causing the battery casing to deform. Among the above three reasons, the expansion of the shell caused by the expansion of the electrode is the most important reason.

The bulging problem of prismatic batteries is a common problem, especially for large-capacity rectangular lithium-ion batteries. Battery bulging will cause an increase in the internal resistance of the battery, local electro-hydraulic depletion, and even casing rupture, seriously affecting the safety and cycle life of the battery.

We propose two solutions:

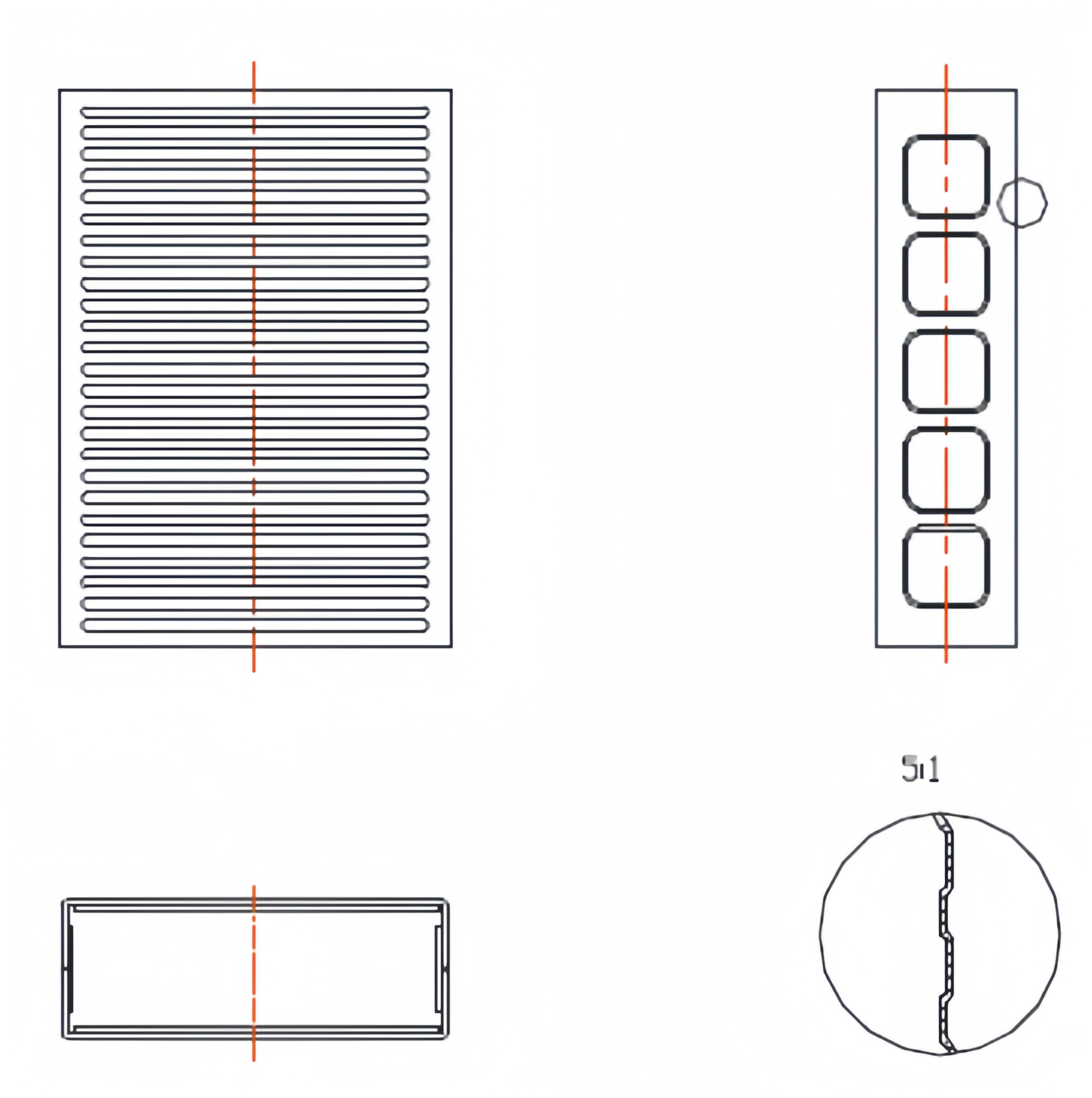

Utilize small structural forms to enhance shell strength.

We designed the original flat shell into a reinforced structure, and tested the effect of the shell’s reinforced structure design by pressing the inside of the shell. The tests were conducted separately according to the different fixing methods (fixed length direction and fixed width direction). The effect of strengthening the structure can be clearly observed. Taking the case of fixed width as an example, under a pressure of 0.3Mpa, the deformation of the shell with reinforced structure is 3.2mm, while the deformation of the shell without reinforced structure reaches 4.1mm, and the deformation is reduced by more than 20%.

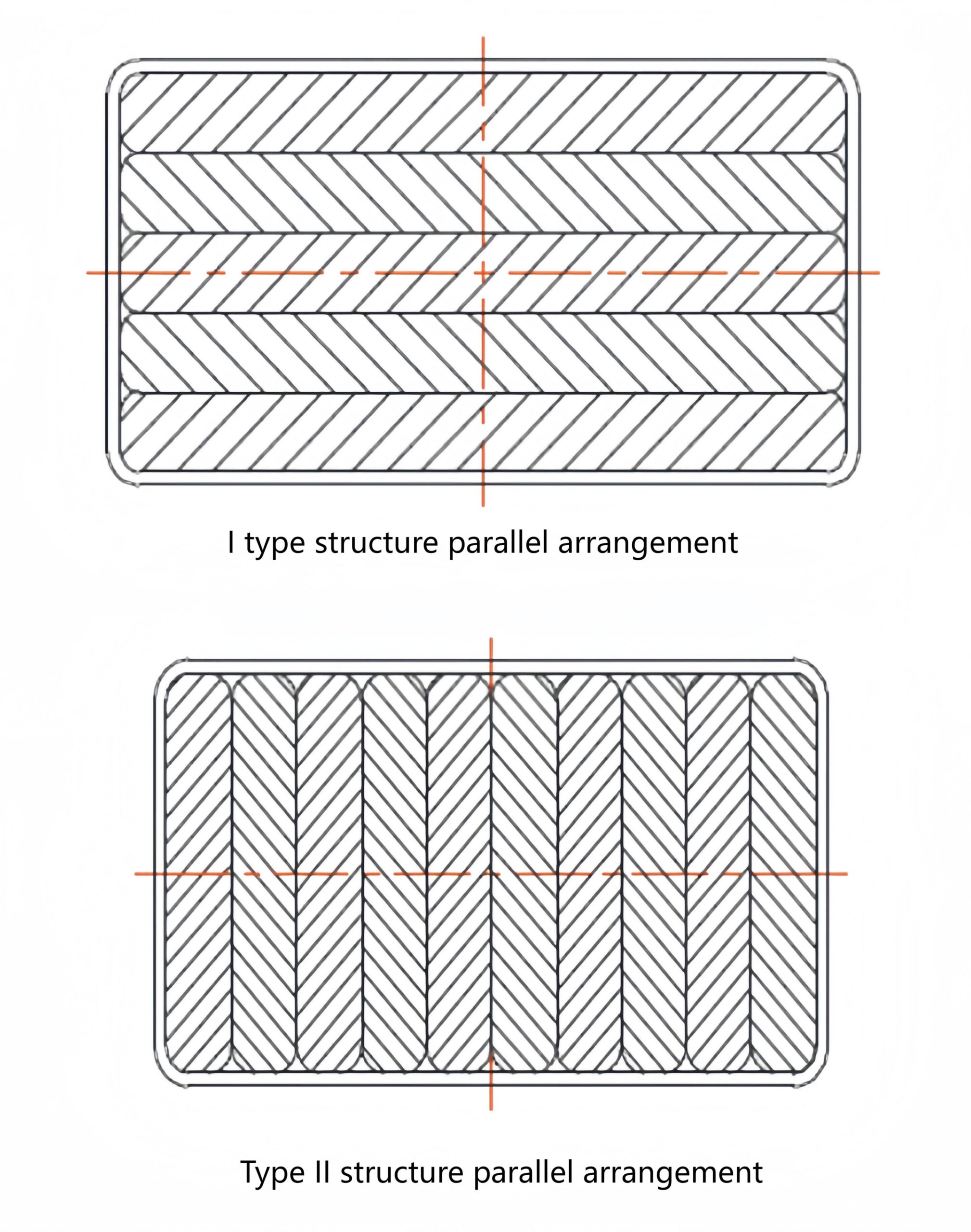

Optimize the arrangement of battery cells in the module

The researchers compared the two arrangement types, as shown in the figure below. The comparison found that the deformation in the thickness direction of arrangement II was significantly smaller than that of arrangement I.

Heat dissipation performance deteriorates

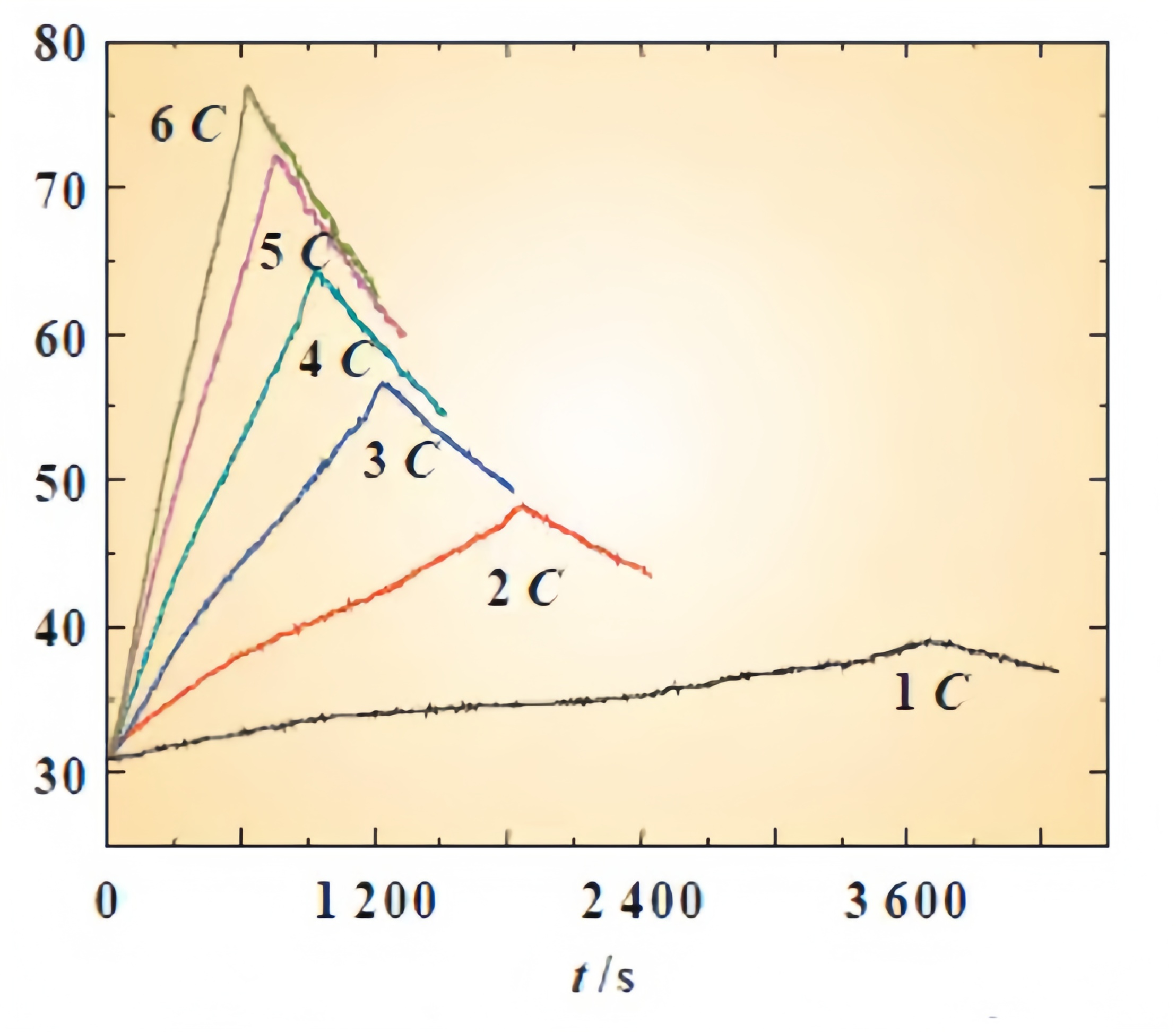

As the volume of the cell increases, the distance between the internal heating part of the battery and the casing becomes longer and longer, and there are more and more conductive media and interfaces, making heat dissipation difficult, and the heat distribution on the cell is uneven. The problem is becoming more and more obvious. We conducted a study using a 3.2 V/12 Ah square lithium-ion battery. During the test, the ambient temperature was 31°C, the heat dissipation method was air cooling, and a temperature monitor was used to record the temperature changes of the battery.

Experimental steps:

1) Pressure charging, use 12A current to charge the battery until the charging cut-off voltage is 3.65V and the current is 1.8A;

2) Leave it aside for 1 hour after charging to allow the battery to stabilize;

3) Constant current discharge, discharge at different rates to the discharge cut-off voltage 2 V. Among them, the discharge rate is set as 1C, 2C, 3C, 4C, 5C and 6C respectively.

As shown in the figure above, it is the temperature change of the battery surface under different discharge rates. It can be seen that as the rate increases, the temperature becomes higher and higher. The maximum battery surface temperatures corresponding to each discharge rate are 38.1, 48.3, 56.7, and 64.4 respectively. , 72.2, 76.9 ℃. During 3C rate discharge, the maximum temperature has exceeded 50 ℃. At 6C, the temperature reached 76.9 ℃ and the time above 50 ℃ was 470 s, accounting for two-thirds of the entire discharge process, which is very detrimental to the safe and continuous operation of the battery.

We propose two solutions

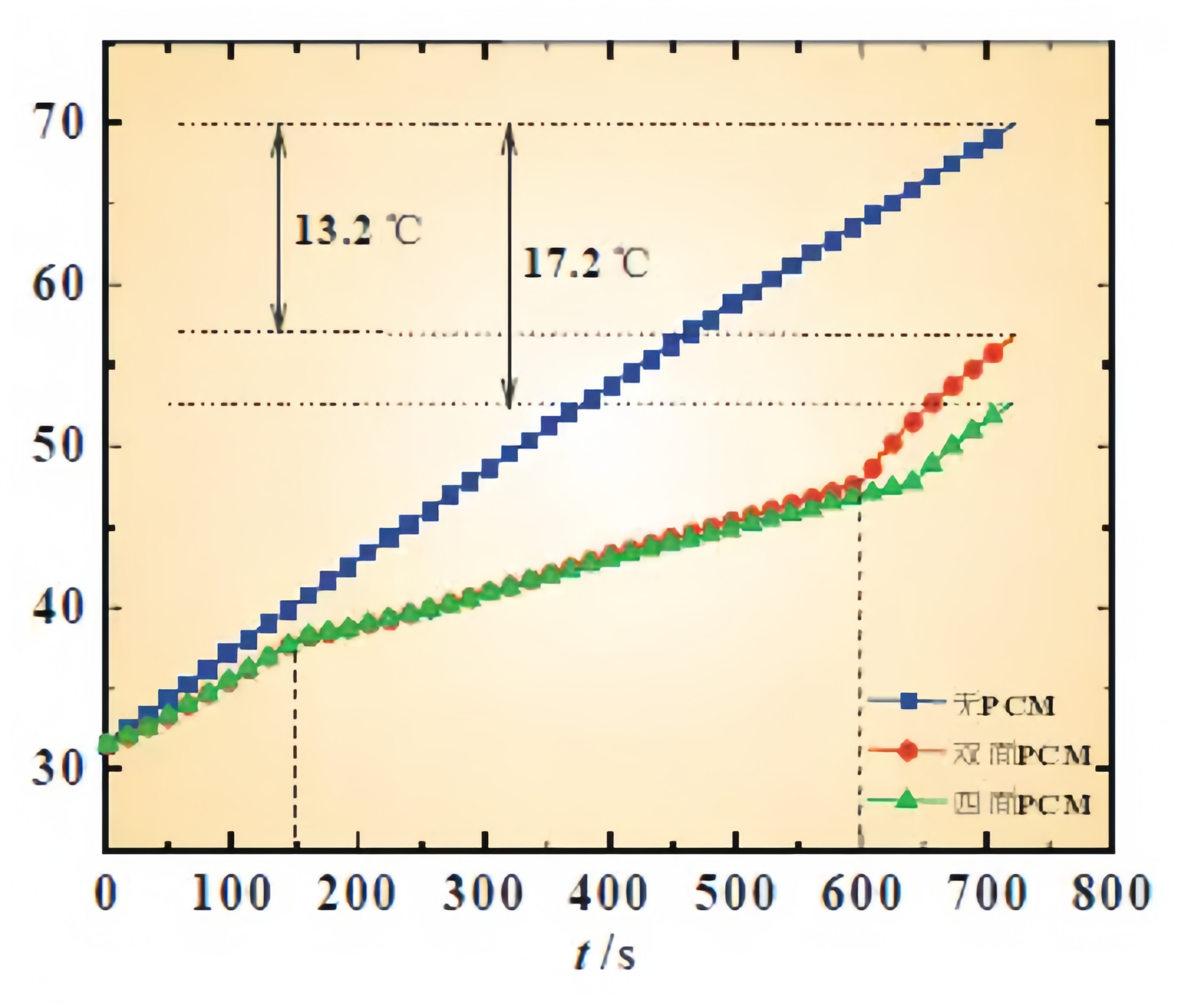

Utilize phase change materials

We use phase change materials as thermal conductive media and attach them to the surface of the single cell. Using double-sided bonding and four-sided bonding, the temperature rise comparison after applying thermal conductive materials is shown in the figure below. The heat dissipation effect is greatly improved.

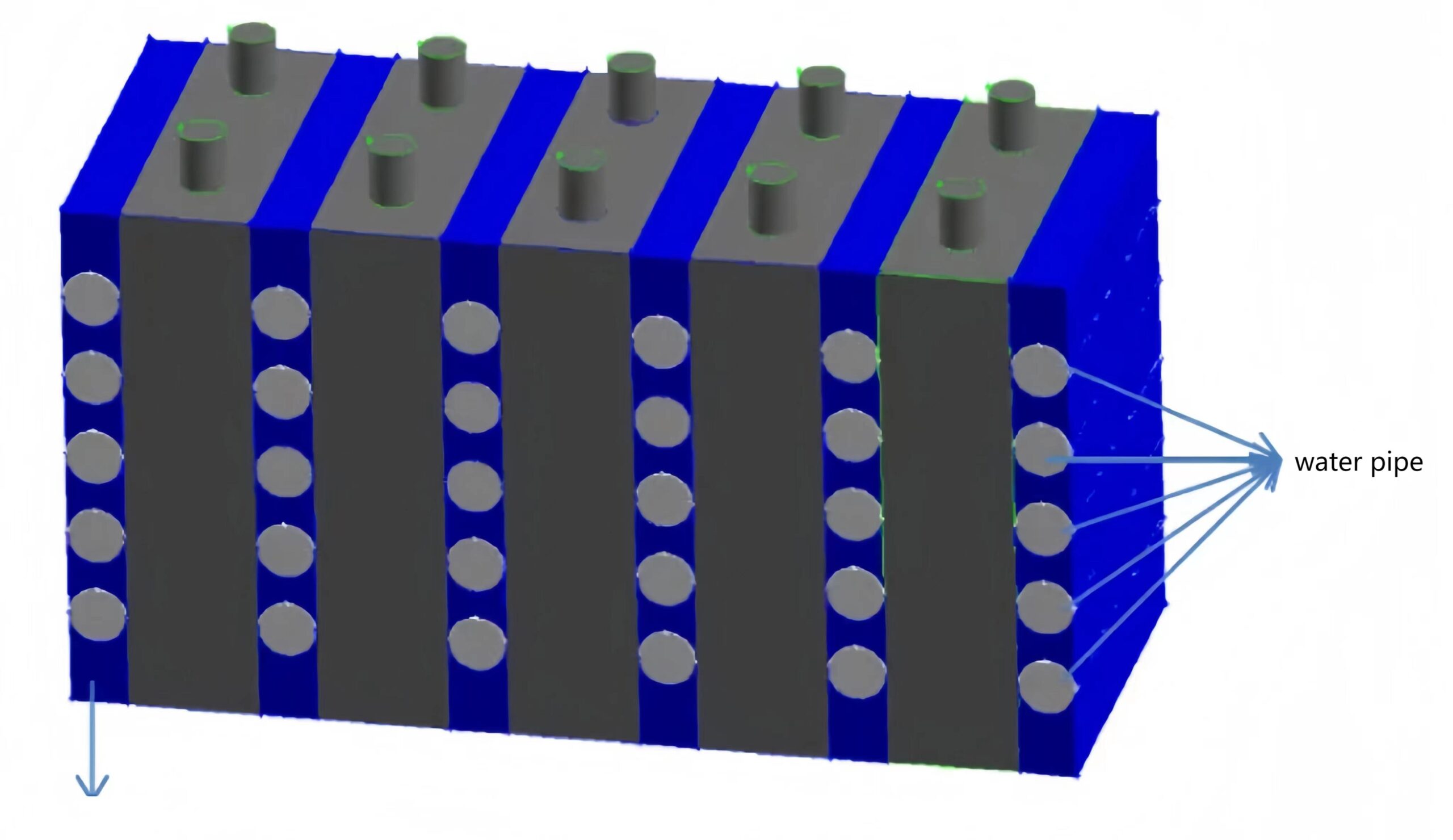

Combine thermal conductive materials with water cooling

Researchers combine thermal conductive materials with water cooling, allowing the water cooling system to transfer the heat absorbed by the thermal conductive materials to the outside of the system. The form is as shown in the figure below:

For lithium battery systems, in order to prevent thermal runaway problems, the most ideal thing is to be able to directly detect the parameters of each cell (the most basic temperature, voltage, current, etc.). In this case, even if there is no new model with good quality, low price and good functions, With the emergence of sensors, early warning and treatment of thermal runaway will also become possible. The small number of cells in the system is one of the important competitiveness of prismatic batteries.