What’s a PV-Plus-Storage system? What is its market prospect? Today We take the US. as an example to analyze how PV-Plus-Storage leads the market.

What’s a PV-Plus-Storage system?

Solar panels have one job: They collect sunlight and transform it into electricity. But they can make that energy only when the sun is shining. That’s why the ability to store solar energy for later use is important: It helps to keep the balance between electricity generation and demand.

-300x211.jpg)

Many solar-energy system owners are looking at ways to connect their system to a battery so they can use that energy at night or in the event of a power outage. Simply put, a solar-plus-storage system is a battery system that is charged by a connected solar system.

Development status of the US

PV-Plus-Storage Plants Dominate Hybrid Power Growth

Berkeley Lab reports significant growth in hybrid power plants that combine wind or solar photovoltaic (PV) generation capacity with batteries for storage. The PV-Plus-Storage subcategory topped this market in 2022.

-300x222.jpg)

PV-Plus-Storage Leads the Market

With 213 plants across the U.S., PV-Plus-Storage is the most common hybrid subcategory. It accounts for 59 of the 62 hybrid facilities added last year. Berkeley Lab reports that hybrid PV-Plus-Storage plants now have roughly the same battery storage capacity as standalone energy storage facilities, at around 4 GW. However, they have more storage capacity than their standalone counterparts, at 12.5 GWh.

-300x104.jpg)

PV-Plus-Storage beats all other hybrid categories in its storage-generator capacity ratio, at 49%, and storage duration, at 3.1 hours. The next-best category for both metrics is fossil-plus-storage, with a 16% storage ratio and a duration of 2.3 hours. In contrast, wind-plus-storage plants have a low average storage ratio of 14% and a short duration of 0.6 hours.

Energy Storage Manufacturing Scales Up

The ongoing growth of hybrid power generation coincides with a boom in domestic manufacturing for components in energy storage systems, solar panels, wind turbines, and other clean energy technologies. According to a report from the American Clean Power Association (ACP), the private sector has announced $271 billion in investments for utility-scale clean energy and manufacturing projects over the last 12 months.

-300x158.jpg)

That includes over $22 billion across 83 new or expanded manufacturing facilities. ACP anticipates a more than fifteenfold increase in grid-scale battery storage production once the announced facilities start operations. Plants aside, battery makers are expanding their manufacturing output as last year’s Inflation Reduction Act (IRA) added new incentives for cleantech production.

The cost of building PV-Plus Storage

That depends on how long you want your storage to last and how much power you want to use.

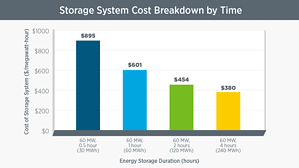

A standalone 60 MW storage system will decrease in cost per megawatt-hour (MWh) as duration increases. Meaning, the longer your storage lasts, the lower the cost per MWh. That’s because the cost of inverters and other hardware account for more of the system’s costs over a shorter period. The system costs range from $380 per kWh for those that can provide electricity for 4 hours to $895 per kWh for 30-minute systems.

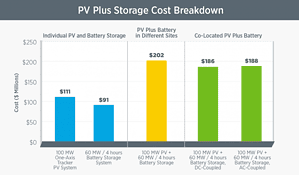

Putting a PV system and a storage system in the same place, known as co-location, enables the two systems to share some hardware components, which can lower costs. Co-location can also reduce costs related to site preparation, land acquisition, labor for installation, permitting, interconnection, and developer overhead and profit. When PV and battery storage are co-located, they can be connected by either a DC-coupled or an AC coupled configuration.

DC, or direct current, is what batteries use to store energy and how PV panels generate electricity. AC, or alternating current, is what the grid and appliances use. A DCcoupled system needs a bidirectional inverter to connect battery storage directly to the PV array, while an AC-coupled system needs a bidirectional inverter and a PV inverter.

Where is this all going?

As solar energy becomes cheaper and more widely used, the market potential for energy-storage devices grows. The challenge is making storage affordable too, with more cost-effective batteries while improving management and integration techniques.Ensuring that electric grid can deploy enough energy to accommodate everyone during peak times at an affordable cost, ensuring the reliability of the grid.