BMS (battery management system) is an indispensable and important component in the battery module. It is the hub for managing and monitoring power batteries. It manages, maintains and monitors various battery modules, and is responsible for preventing battery overcharge and overdischarge, extending battery life, and helping batteries to operate normally.

The main functions of the battery management system (BMS) include: real-time monitoring of battery physical parameters, battery status estimation, online diagnosis and early warning, charge and discharge and pre-charge control balance management, thermal management, etc. Any problem with the above functions will cause fatal harm to the battery. BMS has many design functions, and battery pack protection management and capacity management are two basic functions. There are two key areas of battery pack protection management: electrical protection and thermal protection.

Battery pack protection management

Electrical protection – current

Monitoring battery pack current is an important way to implement electrical protection. Any battery cell is subject to current and voltage constraints. A well-designed BMS will protect the battery pack by preventing operation outside the battery manufacturer’s battery rating.

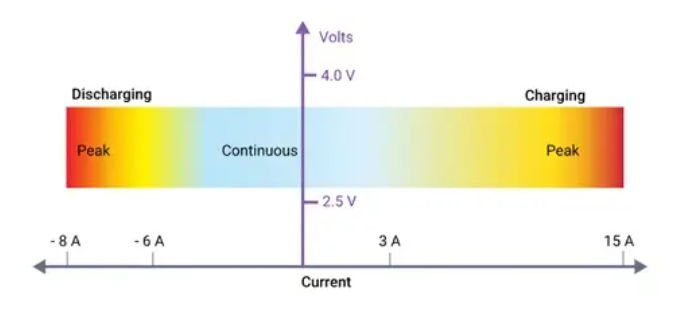

Lithium-ion batteries have different charge current limits and discharge current limits, and both modes can handle higher peak currents. Battery manufacturers usually specify maximum continuous charge and discharge current limits, as well as peak charge and discharge voltage limits. The BMS can monitor the current to decide when to reduce the available current or completely interrupt the current. This requires the BMS to have almost instantaneous sensitivity to extreme current peaks.

Electrical Protection – Voltage

Lithium-ion batteries must operate within a certain voltage range. Any battery pack will experience a large number of current cycles, discharges due to load demands, and charging from various energy sources, so the voltage is usually further limited to optimize battery life.

When approaching the high voltage limit, the BMS can request a gradual reduction in the charge current, or if that limit is reached, it can request a complete termination of the charge current. On the other hand, when approaching the low voltage limit, the BMS will request that the critical active offending load reduce its current demand.

Thermal Management Protection – Temperature

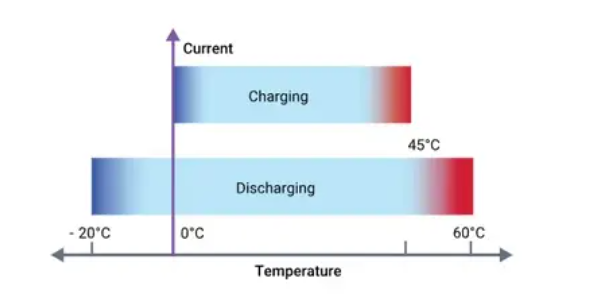

On the surface, Li-ion batteries have a wide operating temperature range, but the overall capacity of the battery is reduced at low temperatures due to the significant slowing of the chemical reaction rates. While they do perform much better than lead acid or NiMh batteries in terms of their capabilities at low temperatures, charging below 0°C (32°F) is physically problematic, so temperature management is very important.

During sub-freezing charging, plating of metallic lithium can occur on the anode. This is a permanent damage that not only results in reduced capacity, but also makes the battery more susceptible to failure if subjected to vibration or other stress conditions. The BMS can control the temperature of the battery pack through heating and cooling.

The thermal management achieved depends entirely on the size and cost of the battery pack as well as the performance targets, the design criteria of the BMS and the product unit, which may include considerations of the target geographic region.

Capacity Management

Maximizing the capacity of a battery pack is one of the most important battery performance features provided by a BMS. Without this maintenance, a battery pack may eventually become useless. Initially, a battery pack may have well-matched cells, but over time, the similarity between cells further degrades, not only due to self-discharge, but also due to charge/discharge cycles, temperature rise, and aging.

The battery pack array of series cells determines the overall battery pack voltage, and mismatches between adjacent cells can cause dilemmas when trying to charge any battery pack. Figure 3 shows why this is the case. If one has a perfectly balanced group of cells, then all is well, as each cell will charge in an equal manner and the charge current can be cut off when the 4.0 voltage cap threshold is reached. However, in an unbalanced situation, the top cell will reach its charge limit early and the charge current to the branch will need to be terminated before the other bottom cells can be charged to full capacity.

Recap

The main purpose of the battery management system is to ensure the design performance of the battery system. In terms of safety, the BMS battery management system can protect the battery cells from damage and prevent safety accidents; in terms of durability, the BMS battery management system can make the battery work in a reliable and safe area and extend the battery life; in terms of power, the battery’s working state is maintained to meet the equipment’s operating requirements.

The battery management system can balance the power of each battery in the battery pack, analyze and calculate the power of the battery pack and convert it into understandable endurance information to ensure the safe operation of the power battery.