In the wave of modern industrial development, lithium batteries have become the power heart of many industrial applications due to their advantages such as high energy density, long life and environmental friendliness. From the light flight of drones to the continuous operation of heavy machinery, lithium batteries are everywhere, and their stability and efficiency are crucial to ensuring the smooth flow of industrial activities.

However, the diversity and complexity of industrial environments require that lithium batteries are not just a general energy solution, but high-tech products that need to be carefully customized according to specific use environments and conditions.

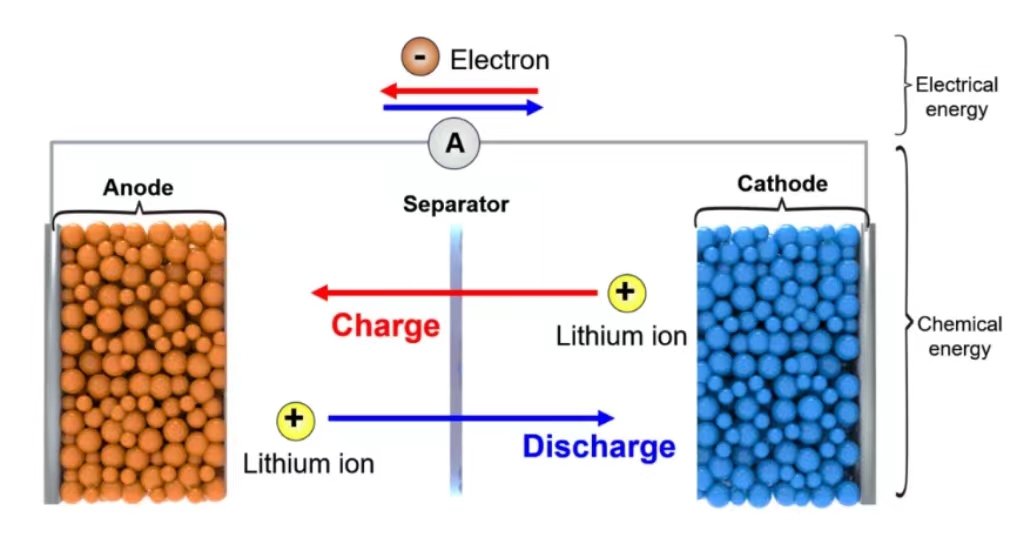

The working principle of lithium batteries is based on the movement of lithium ions between positive and negative electrode materials. When the battery is discharged, lithium ions move from the negative electrode to the positive electrode, releasing energy through the external circuit; when charging, lithium ions move from the positive electrode back to the negative electrode.

This process seems simple, but in fact it involves complex chemical reactions and physical changes, which are affected by various factors such as temperature, pressure, current and voltage. Therefore, the design and manufacturing of lithium batteries must take these factors into consideration to ensure that the battery can work stably and reliably in a specific industrial environment.

Considerations:

When using lithium batteries in industrial areas, the first thing to consider is the environmental conditions. Different industrial areas may face extreme temperature changes, humidity fluctuations, dust contamination, and potential chemical corrosion.

For example, lithium batteries operating in high-temperature environments need to have good thermal stability to prevent performance degradation or safety hazards caused by overheating; while in cold areas, batteries need to be able to maintain effective energy output at low temperatures. In addition, possible vibrations and shocks at industrial sites also place higher requirements on the structural strength of lithium batteries.

In addition to environmental factors, the operating characteristics of industrial equipment are also important aspects that must be considered when customizing lithium batteries. Different types of industrial equipment have different power requirements. Some require large current for short-term release, while others require small current for long-term power supply. The energy density, power density, cycle life, charge and discharge rate and other parameters of lithium batteries need to be optimized and designed according to the specific requirements of the equipment.

For example, for equipment that frequently starts and stops, lithium batteries need to have fast response charge and discharge capabilities and high cycle durability; while for equipment that works continuously for a long time, more emphasis is placed on the long-term stability and energy utilization efficiency of the battery.

Safety is another key consideration when using lithium batteries in industrial areas. Although lithium batteries are relatively safe, there is still a risk of thermal runaway and fire under extreme conditions.

A variety of safety measures need to be taken when customizing lithium batteries, such as using a high-quality battery management system (BMS) to monitor the status of the battery and prevent overcharge, over-discharge, short circuit, etc.; at the same time, the battery shell material and The structural design must also be able to withstand external physical damage and chemical erosion.

In the era of Industry 4.0, improvements in intelligence and automation have made industrial equipment’s power requirements more stringent. As a key component to support the operation of these equipment, lithium batteries’ performance directly affects the efficiency and reliability of the entire production process.

Therefore, when choosing a suitable lithium battery pack, we must not only consider the above-mentioned environmental adaptability, equipment matching and safety, but also consider the degree of intelligence of the battery, such as whether it can be seamlessly connected with the equipment control system to achieve status monitoring and Fault warning and other functions.

Customized services for MK batteries

The use of lithium batteries in industrial areas is a complex decision-making process involving many considerations. From the basic performance of the battery to the customized needs to adapt to specific environments, to the compatibility with industrial equipment and the level of intelligence, every detail is related to whether lithium batteries can maximize their performance in industrial applications.

Traditional standard lithium batteries are difficult to fully meet the diverse needs of different users, while customized lithium batteries can be optimized according to specific needs to provide more personalized and efficient energy solutions.

First of all, lithium battery customization can customize the capacity according to user needs. Different users have different needs for energy capacity. Some users require high capacity to meet the needs of large amounts of energy storage, while other users may be more focused on small, portable energy storage devices. Through customized design, lithium batteries can provide different capacity options according to user needs, ensuring that they can meet users’ specific energy needs.

Secondly, lithium battery customization can meet the power requirements of different application scenarios. Different application scenarios have greatly different requirements for power output. For example, electric vehicles require high power output to provide strong power, while home energy storage systems may require stable power output to meet daily electricity needs. Through customized design, lithium batteries can provide corresponding power output capabilities according to the requirements of different application scenarios to ensure optimal system performance.

In addition, lithium battery customization can also provide specific life requirements according to user needs. Different users have different concerns about the service life of lithium batteries. Some users value long life to reduce replacement costs, while other users may require high cycle life to meet frequent charging and discharging needs. Through customized design, lithium batteries can optimize the cell structure and management system to provide solutions that meet users’ specific life requirements.

Finally, lithium battery customization can also be adaptively designed according to specific environmental conditions. Different environmental conditions may affect the performance and safety of lithium batteries, such as working environments at extreme temperatures or use scenarios at high altitudes. Through customized design, lithium batteries can be optimized in terms of material selection, cell structure and heat dissipation system to adapt to different environmental conditions and ensure stable operation and safety performance of the system.

In summary, when selecting lithium batteries in industrial zones, they should not just focus on price and brand, but should have an in-depth understanding of the battery’s technical parameters and usage environment, and work closely with professional battery manufacturers to customize the lithium battery pack that best suits their needs. To promote the development of industrial activities in a more efficient, safe and sustainable direction.