With the advancement of science and technology, the labor advantage that the manufacturing industry has long relied on is gradually disappearing. Replacing labor with machines can reduce costs to a large extent and effectively improve work efficiency. For large-scale manufacturing plants, the only way to improve productivity is through technological improvement and the introduction of automation and intelligent technologies. Automation is the only way for factory development.

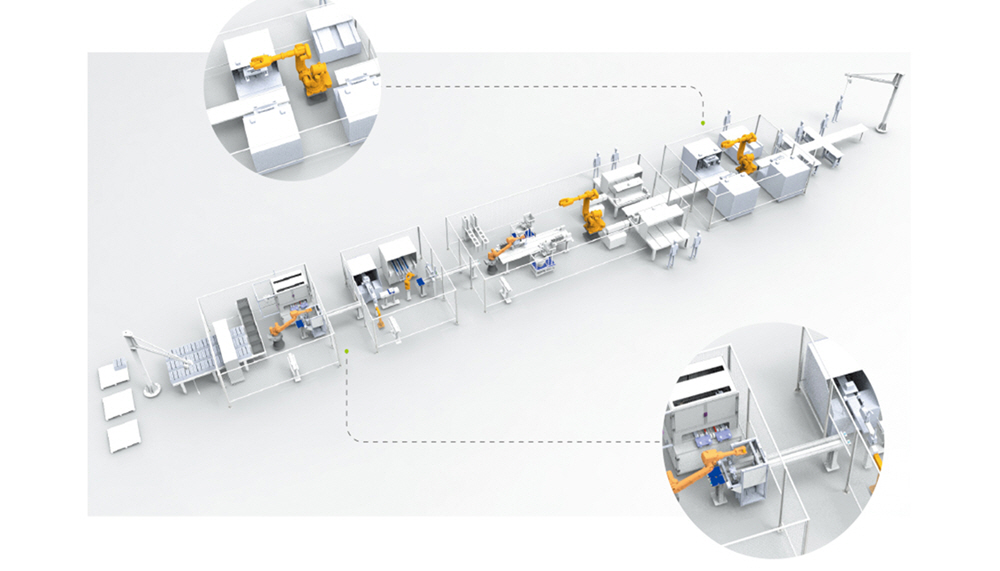

Automatic line process

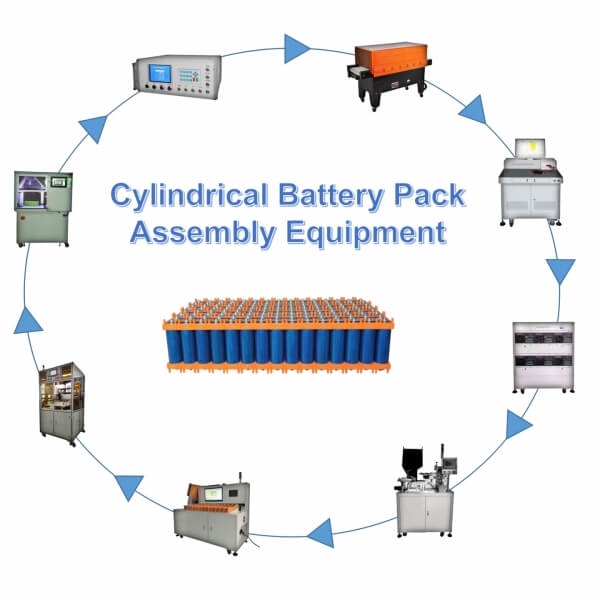

In order to meet the needs of production, many lithium battery pack factories usually need to install a set of automated production equipment to automate the assembly of lithium battery packs. Lithium battery assembly mainly includes: battery cell stickers, battery cell sorting, battery cell placement bracket nickel sheets, battery pack welding, battery pack protection plate BMS welding, etc. Let the machine complete simple self-operation and processing, and the workers, machinery and automated instruments become a system that can achieve coordinated operation and control and be continuously optimized.

Advantages of factory automation

First, mechanical manufacturing automation technology can greatly improve production efficiency, shorten product production cycles, and provide time guarantee for products to seize the market.

Second, improving the company’s external image and showing the company’s production efficiency can ensure that product quality meets standards and specifications are unified, and increase orders. It has good development prospects for enterprises.

Third, automated equipment runs through part of the lithium battery pack manufacturing process, which can minimize the consumption of manpower, material and financial resources. Improve production efficiency and reduce labor consumption and use, thereby helping companies reduce production costs and improve their economic benefits.

Fourth, automation technology uses standardized production, which can reduce and reduce the consumption of raw materials caused by human uncertainty factors in the production process and reduce the generation of waste.

Fifth, unlike humans, automated equipment and robots do not experience fatigue. There’s no question about boredom or losing focus, and naturally, they don’t make many mistakes. Industrial automation systems are more accurate than manual systems and eliminate the element of human error. This not only results in a higher quality product, but also a more consistent product.

Automated production line at MK factory

At the MK Lithium Battery pack factory, the automated production line stands as the epitome of efficiency and precision. As soon as the raw materials are fed into the system, a symphony of robotic arms, conveyor belts, and automated machinery takes over, orchestrating a seamless flow of production. Each component undergoes meticulous inspection and assembly, guided by advanced sensors and algorithms to ensure utmost quality and consistency. From cell formation to module integration, every step is meticulously choreographed to minimize waste and maximize output, showcasing the pinnacle of modern manufacturing technology.

With state-of-the-art automation, the production line at MK Lithium Battery pack factory not only accelerates the pace of manufacturing but also elevates the standards of safety and reliability. Human intervention is minimized to strategic oversight and maintenance, as the machines tirelessly execute tasks with unparalleled precision and consistency. This integration of automation not only streamlines the production process but also fosters innovation, allowing for rapid adaptation to evolving market demands and technological advancements. As a beacon of efficiency and innovation, the automated production line stands as a testament to MK Lithium’s commitment to delivering cutting-edge solutions in the realm of energy storage.

In short, having a complete set of automation equipment can effectively improve production efficiency and ensure consistency of product quality. MK is committed to completing the modernization of the factory. To learn more about MK battery products and factory conditions, please feel free to contact us.