Optimizing Rack Mounted Li-ion Battery Charge and Discharge Profiles

Rack-mountable lithium-ion batteries are the backbone of modern backup power systems, providing reliability and flexibility for various applications. To realize its full potential, it is essential to optimize its charge and discharge curves. Therefore, in this sharing, we will talk to you about optimizing the angle and the strategies and techniques to achieve their best performance and extend the service life of Rack Mounted Li-ion Battery.

The importance of correct charging profile

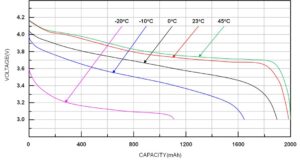

The charge curve of a rack-mounted lithium-ion battery plays a vital role in its performance and longevity. Lithium-ion batteries are sensitive to overcharging, which can lead to capacity loss and even safety hazards. To optimize the charging process, you must implement a charging profile that conforms to the battery manufacturer’s recommendations. This includes setting appropriate voltage limits, current limits, and temperature thresholds. A key aspect of optimizing your charging profile is balancing charging speed and battery health. Setting too quickly or using high voltage can cause heating and potential thermal runaway, a safety issue. On the other hand, putting too slowly may not be efficient for applications that require fast power. For example, the picture below

Charging curve

Rack Mounted Li-ion Battery: Smart Charging Technology

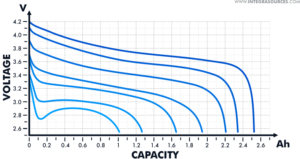

To further enhance the charging process, advanced charging algorithms can be employed. These algorithms are designed to adapt to the battery’s state of charge, temperature, and capacity. They ensure the battery is always charged optimally, reducing the risk of overcharging and maximizing efficiency. Intelligent battery management systems (BMS) often control these algorithms and monitor battery health in real time. Advanced charging algorithms extend the life of lithium-ion batteries by preventing overcharging and over-discharging, two significant factors that cause capacity to decay over time. These algorithms also balance the individual cells within the battery pack, ensuring that all cells receive an equal share of charge and discharge cycles, thus promoting even aging. For example, the picture below

battery management system

Discharge curve of Rack Mounted Li-ion Battery

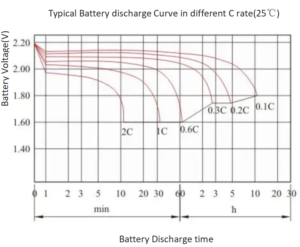

For rack-mounted lithium-ion batteries, optimizing the discharge profile is as essential as charging. The discharge curve determines how the battery draws power and affects its performance. Implementing the correct discharge profile ensures the battery operates efficiently while minimizing wear and tear. The discharge profile of a rack-mounted lithium-ion battery depends mainly on the specific application it serves. For example, in a data center environment, where batteries are used in uninterruptible power supplies (UPS), the discharge profile should be optimized to deliver power to critical equipment during a power outage quickly. This requires a balance between discharge rate and discharge depth. For example, the picture below

Discharge curve

Rack-Mountable Lithium-Ion Batteries: Load Management

Rack-mounted lithium-ion batteries are often used for load shedding and peak shaving, which involves drawing power from the battery during periods of peak demand. By carefully managing these operations, power costs can be reduced and battery life extended. Implementing software solutions that analyze load patterns and automate load shedding can help optimize discharge profiles. Load shedding is a strategy industries use to reduce electricity consumption during peak demand periods. By reducing non-essential loads or relying on battery power during these times, organizations can save on power costs and reduce stress on the grid. Peak shaving involves smoothing energy usage patterns to avoid peak demand charges from utility providers.

Regular monitoring and maintenance

Optimizing the charge and discharge profiles of rack-mounted lithium-ion batteries is an ongoing process. Regular monitoring, maintenance, and capacity testing are essential to ensure your battery continues to perform at its best. Over time, a battery’s capacity may decrease, and you may need to adjust charge and discharge profiles to maintain efficiency and reliability.

Regular maintenance is a critical component of optimizing rack-mounted lithium-ion batteries. This includes capacity testing to assess the health of the batteries and determine if any need replacing. It also involves cleaning the battery terminals and ensuring all connections are tight. Monitoring your battery’s performance and adjusting as needed is critical to extending lifespan.

Improve performance through continuous optimization

Remember, a well-optimized lithium-ion battery is not only efficient but also cost-effective in the long run. Whether it’s a data center, telecommunications facility, or industrial application, optimized rack-mountable lithium-ion batteries can be a valuable asset in powering your operations. As a global battery supplier, MK Energy will continue providing reliable battery solutions. To learn more about batteries and industry consultation, please visit our official website 【https://www.mkenergycn. com/】