Simplified production for Wall mounted lithium battery manufacturer

Complex and manpower-intensive wall-mounted lithium battery manufacturers are no longer the mainstream. To improve their core competitiveness, they must simplify production and improve efficiency. This article will share how a wall-mounted lithium battery manufacturer simplifies the production process to meet the growing market demand effectively.

Use automated assembly lines

Automation is vital in wall-mounted lithium-ion battery manufacturing at every production stage. From the initial manufacturing of battery components to final assembly and testing, robotic systems and intelligent machines perform tasks accurately and quickly. The margin of error is reduced, and the overall production cycle is accelerated. Automated assembly lines also provide consistent and high-quality output. The machines can perform repetitive tasks, ensuring consistent battery production. This standardization is critical for producing wall-mounted lithium-ion batteries, as consistency directly affects performance and safety.

Wall-mounted lithium battery manufacturer adopts innovative manufacturing technology

As a manufacturer of wall-mounted lithium-ion batteries, intelligent manufacturing technology can enhance the control and predictability of the production process to improve product quality and core competitiveness. We use sensors, actuators, and data analytics to monitor and control all aspects of the manufacturing process. This level of automation provides real-time insight into production conditions, allowing manufacturers to optimize parameters to improve efficiency and quality. Additionally, we use advanced data analysis and machine learning algorithms to analyze the large amounts of data generated during manufacturing. This identifies anomalies and potential issues to minimize downtime and reduce the risk of defects. We also integrate various components of the production process, creating a seamless flow of information and resulting in a more synchronized and responsive production line.

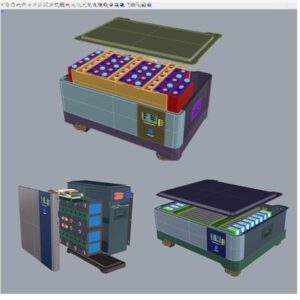

Modular design concept from wall-mounted lithium battery manufacturer

We break down the battery system into modules, each with a specific function. These modules (such as batteries, control electronics, and housing) are designed to be easily replaced and upgraded. This modularity simplifies manufacturing and enables more efficient maintenance and upgrades over the battery’s life. Battery configurations can also be customized for specific residential, commercial, or industrial energy storage needs. The modular design can also speed up our assembly time and improve delivery speed. At the same time, when components within a module require maintenance or replacement, it can be done without disrupting the entire system, minimizing downtime and costs.

Supply chain of wall-mounted lithium battery manufacturers

Strengthening the supply chain is also an important aspect of streamlining production, with close collaboration with suppliers ensuring the stability and reliability of raw materials. Regular, open lines of communication can help wall-mounted lithium-ion battery manufacturers and suppliers stay abreast of market trends, demand fluctuations, and more. This exchange of information enables proactive decision-making, reduces the risk of outages, and ensures timely availability of components. These measures optimize the supply chain, shorten delivery times, and minimize the risk of excess or inventory shortages.

Promote manufacturing innovation

Continuous research and development as a manufacturer of wall-mounted lithium-ion batteries contributes to technological advancements and performance improvements that enhance the competitiveness and functionality of these energy storage solutions. Continuously explore new and improved battery components materials, such as cathodes, anodes, and electrolytes, to improve energy density, cycle life, and overall battery performance, laying the foundation for more efficient and durable energy storage systems. Research and development of battery management systems (BMS) and control electronics play a crucial role in optimizing individual batteries’ performance, ensuring safety, and extending the overall service life of the battery. Improving manufacturing: Our processes can simplify battery assembly, reduce production costs, and increase efficiency.

Simple summary

As any wall-mounted lithium-ion battery manufacturer, to improve the overall efficiency of the factory, it must adopt automated assembly lines, innovative manufacturing technologies, etc. With the arrival of Industry 4.0, various manufacturing plants will gradually become popular. Only in this way can we significantly improve our efficiency and promote production.