Batteries are a widely used energy storage tool at this stage. Their development is also accompanied by various safety issues. In order to ensure the quality, safety and reliability of battery products, market supervision agencies in various countries have increased their supervision of battery products, and battery exports require multiple certifications and tests.

Common battery certification

IEC certification

The international standards for lithium batteries issued by the International Electrotechnical Commission, including IEC 62133, IEC 62619, etc., involve battery design, safety, performance, electrical characteristics, etc., and are an important basis for IECEE-CB certification. At present, these standards have become an important basis for access to markets in countries such as Japan, South Korea, Thailand and India.

UL certification

The lithium battery safety certification of the US safety laboratory, including UL 1642, UL 2054 and other standards, involves battery safety performance, electrical performance, temperature cycle and other aspects, and is suitable for North America.

UN38.3 certification

The lithium battery safety certification of the United Nations dangerous goods transportation test involves the mechanical, electrical, thermodynamic, impact and other aspects of the lithium battery to ensure the transportation safety of battery products. It belongs to safety and performance testing, and the scope of application almost covers the world.

CE Certification

The EU’s mandatory product quality and safety certification is regarded as a passport for manufacturers to open and enter the European market. CE certification testing projects include EMC electromagnetic compatibility testing of batteries, LVD safety testing, etc.

RoHS Certification

The certification of the EU’s Restriction of Hazardous Substances Directive is mainly used to standardize the materials and process standards of electronic and electrical products to make them more conducive to human health and environmental protection. The standard stipulates that harmful substances in battery products, such as lead, mercury, cadmium, etc., are mainly tested.

MSDS report

MSDS, or Material Safety Data Sheet, is a document used by chemical manufacturers and importers to explain the physical and chemical parameters of chemicals, health hazards, safe use and storage, leakage disposal, first aid measures, etc. At present, developed countries such as the United States, Japan, and the European Union have generally established and implemented the MSDS system.

In addition, different countries have their own certification standards, such as South Korea’s KC certification and Japan’s PSE certification. Battery manufacturers need to comply with relevant standards when producing and exporting battery products to ensure product quality and safety performance.

Core tests for battery certification

In the battery certification report, there are several core tests that require special attention during the battery production stage.

Basic performance test

This is the most basic evaluation of the battery, including the battery’s capacity, open circuit voltage, maximum charge/discharge current, and operating temperature range. Through these data, we can preliminarily determine the battery’s energy storage capacity and applicable scope.

Cycle life test

Cycle life is an important indicator for measuring the service life of a battery. Under a certain charge and discharge current, how many charge and discharge cycles can a battery undergo without significantly reducing its performance. Usually, battery manufacturers provide data on the number of cycles at different depths of discharge (DOD).

Safety performance test

Safety is one of the most critical considerations for batteries. The certification report will list in detail the battery’s performance under extreme conditions such as overcharge, overdischarge, short circuit, high temperature, extrusion, and puncture to ensure that the battery will not explode or catch fire under abnormal conditions.

Environmental adaptability test

Considering that the battery may be used in different environments, such as high and low temperatures, humidity changes, etc., this part of the test is designed to evaluate the stability and reliability of the battery in these environments.

Electrochemical performance analysis

This involves more professional electrochemical parameter measurements, such as internal resistance, electrode potential, electrochemical reaction kinetics, etc., to gain a deeper understanding of the working mechanism of the battery and potential improvement directions.

Batteries also need customized certification and testing according to different application scenarios and needs, such as temperature cycle testing, safety testing, capacity testing, etc. Through these rigorous tests and evaluations, it is ensured that the battery provides users with efficient energy while also having the necessary safety guarantees.

Recap

Battery certification is a complex and meticulous process, which covers multiple aspects from basic performance to safety, from environmental adaptability to electrochemical characteristics. With the continuous advancement of technology and changes in market demand, battery certification standards are also constantly updated.

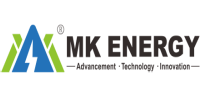

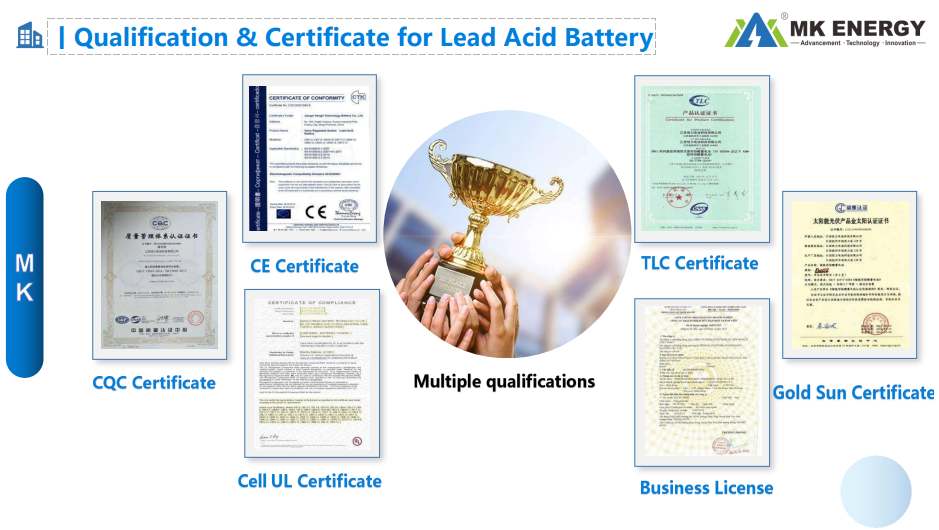

MK continues to pay attention to the latest developments in the industry and continuously improves its product certification system to ensure the advancement and compliance of products and improve competitiveness. If you need batteries, please contact us at sales@mkenergycn.com!